Birds navigate the skies with effortless grace, utilizing every updraft and thermal current. We aspire to capture this natural intuition, moving beyond simple mechanics to achieve a state of true, instinctual flight.

Humans have always dreamed of flight

Scroll down to learn about turning the dream into a reality.

Birds navigate the skies with effortless grace, utilizing every updraft and thermal current. We aspire to capture this natural intuition, moving beyond simple mechanics to achieve a state of true, instinctual flight.

Planes, Jets, and Helicopters are undeniable feats of engineering that have connected the globe. However, they are not the flying experience we dream of; enclosed in pressurized cabins, they lack the immersive, personal connection to the air itself.

Hang gliders, wingsuits, and parasails are amazing recreational achievements that bring us a step closer to true flight. Yet, they often rely on gravity or specific weather conditions, falling short in active control, speed, and total self-propulsion.

Innovations like the Jetson 1 and Jetman are massive modern improvements, yet they still fall just short of the true immersion and control we dream of. The FALCON is the next evolution in human flight, fulfilling these deficits to create a seamless extension of the body.

Here is how the FALCON will take us to our next evolution of human flight:

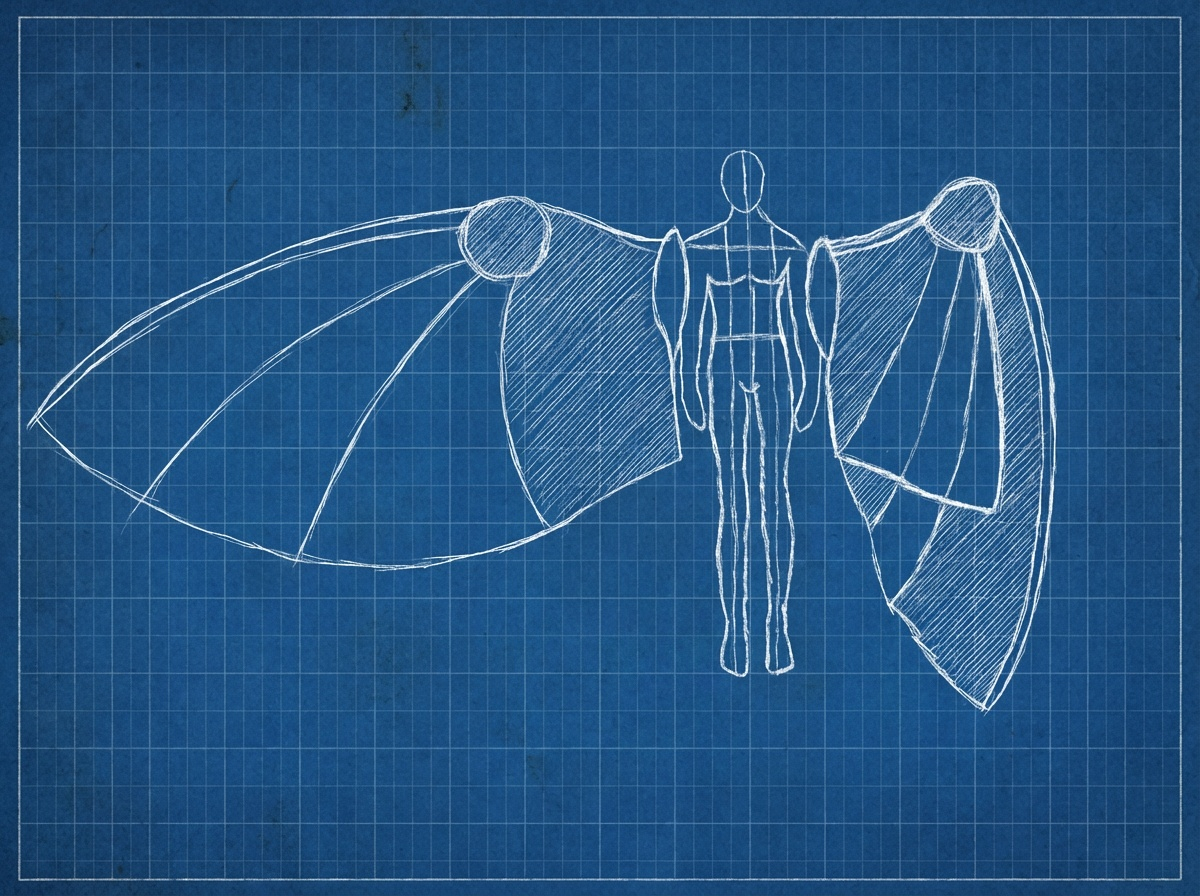

By changing shape mid-flight, we optimize aerodynamics for the desired position, mimicking the precision of biological flight.

A carbon fiber skeleton and Dacron sailcloth patches will provide the wing with a light-weight and strong structure.

In case of emergency, the wings will detach from the suit and pull out a parachute with it, carrying the pilot to safety.

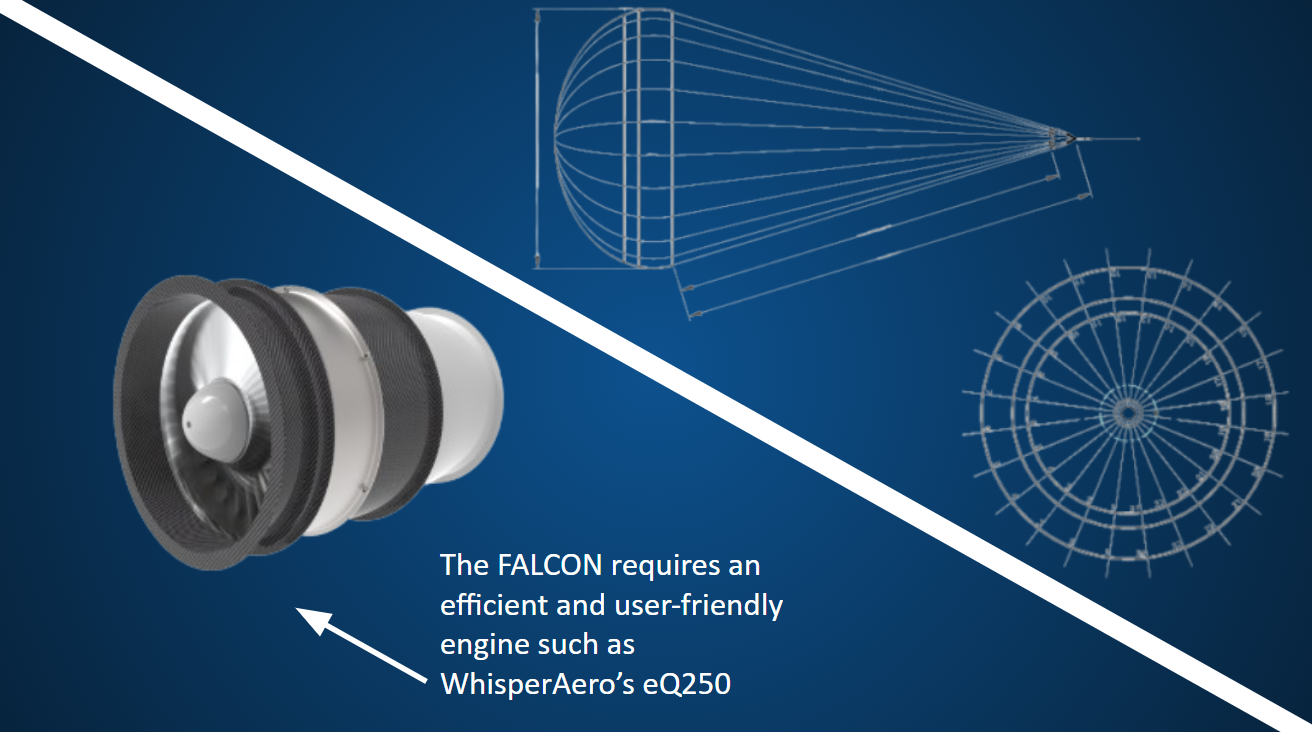

High-torque electric turbines provide necessary vertical lift without the bulk of combustion, ensuring a seamless flight profile.

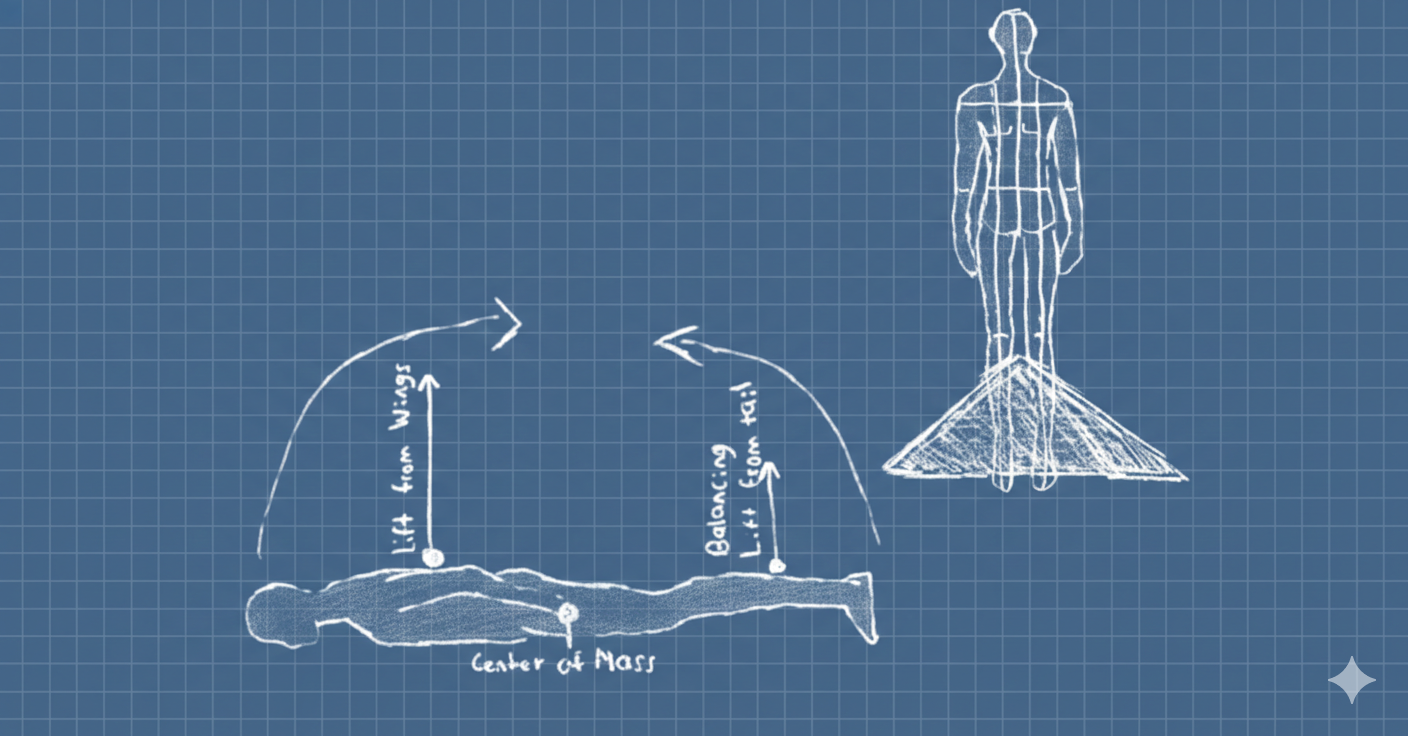

The large surface area of the tail will balance the large amount of lift from the wings and eliminate unwanted instabilities.

The pilots physical movements will control the tail dynamics, prodividing an immersive and stable flight experience.